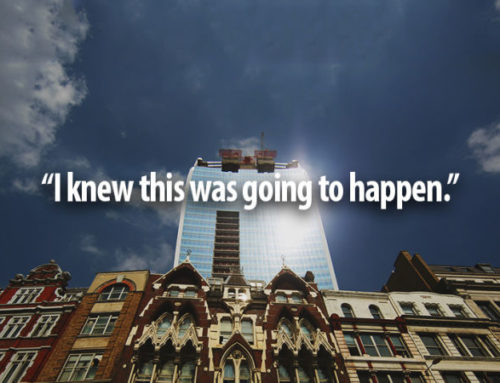

The message this month is dealing with concrete cracks. I know, I know, – you guys already know all about this and I am speaking to an educated audience. It has been drilled into your heads that we need to keep excess water out of the concrete mix and we need to take measures to keep the top of the concrete slab from drying too fast from weather conditions and of course we all know that we use control joints (saw joints) to coax the concrete into cracking where we want it to. So if we know all of this, why does this still happen:

In these photos it appears that our concrete needed a little more “coaxing” since it decided to do its own thing right next to a control joint.

The Cause:

Timing. I prefer to think of concrete slabs as being like my wife. She is patient with me but there is definitely a limit to that patience and when her patience has run out something is going to happen! If you don’t get the control joints installed quickly enough, the slab “loses its patience” and creates its own crack paths and then is too late and no amount of coaxing will change its mind (like my wife). In the photo on the left, the control joints were cut the day following the placement with a quickie saw. The slab on the right was cut on the same day with a soffcut saw but they had problems and the cutting process took much longer than anticipated. In both cases the person making the cuts could not see the random cracks forming as they were nearly microscopic at the time the slab was cut but as the concrete continues to shrink over the next several days, it completely ignores the control joints and uses the original path that was established.

We have a third party testing agency verify the slab subgrade, the slab reinforcing, the concrete properties and the final slab flatness and levelness, but the timing of the control joint installation is never addressed. One time I did see a concrete specification that called for the joints to be installed within 24 hours of placement but for the most part there is nothing within a set of construction documents that addresses this.

In response, our firm has this added to our 033000 specifications under Part 3 – Execution, subheading “Joints” the following text “Control joints indicated on the drawings shall be installed within 4 hours of finishing the concrete. Contractor shall have the necessary resources to meet this specification including, but not limited to, back-up equipment and additional personnel.” This is a tight spec that is difficult to meet. A lot of contractors do not want to install the joints before they spray the curing compound onto the slab. They don’t want to have to clean off the concrete dust first for fear that some of that dust will get trapped under the curing compound and look unsightly. This is easily overcome by thoroughly brooming off the dust and following up with some compressed air. I even saw a company using a leaf blower for this. If you really want to ensure the success of your slabs, all of this needs to be discussed in a pre-construction meeting where you can make sure the contractors knows about this requirement and can act accordingly rather than pointing to the spec book after failure has occurred. The site for the photo on the right was out of state where they used a much harder aggregate in their concrete compared to the limestone we see more often. This aggregate ate their blades and progress was much too slow. These things need to be discussed in advance especially with contractors who are from outside the area and may not be familiar with local issues like this.

By working together we can solve the crack epidemic.

By Travis Miller